Institut Charles Sadron Plateformes

The Micro and Nano Mechanics platform gives access, for academic and industrial collaborations, innovative techniques of the ICS developed to study surface properties of polymers with a in-situ vision.

The hole equipment allow to probe the matter with various speeds, temperatures and relative humidities ; and to work at various scales from a few nanometers to the millimeter scale. The platform possesses also volumic properties characterization assays and an instrumented X-Ray tomograph for >em>in-situ>/em> mechanical assays (compression and indentation).

Surface properties characterization

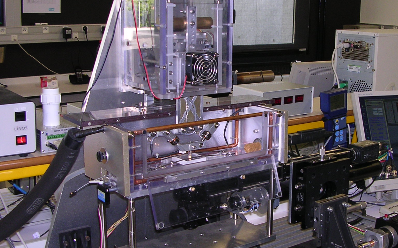

1. Instrumented scratch test apparatus

This instrument is dedicated to mechanical properties measures of solid polymer surfaces by in-situ vision.

Main functions:

- Scratch tests

- Indentation tests (creep and recovery of the contact)

- Scratch fatigue tests

Main characteristics:

- In-situ vision of the contact between indenter and surface during tests.

- Temperature : -50 to 110°C and controlled hygrometry.

- Scratch sliding speed : 1um/s to 10mm/s.

- Normal load from 0.1 to 25N and different indenter geometries (1MPa to 1GPa contact pressure).

- Indenter (spherical, conical, pyramidal, …) of curvature rays comprised between 10µm and 25mm.

Complementary equipment:

- Laser interferometry to follow the evolution of imprint recovery.

2. NanoIndenteur – NanoScratch

Instrument dedicated to the measurement of mechanical properties of surfaces by nano indentation and nano scratch.

Main characteristics:

- Normal load from 0.05mN until 100mN.

- Penetration depth until 50 µm.

- Environmental chamber (control of temperatures, humidity, pressure) and test plate with controllable temperature.

- Contact area measurements by in-situ vision.

Complementary equipment:

- Nanoscratch: measurable force range from 0,05mN to 1N and scratch speed from 0.1µm/s to 10mm/s.

- Optical microscopy.

- AFM: cartography of 40µm x 40 µm and Z of 4µm.

3. High load tribometer

Instrument dedicated to the measure of mechanical properties of non-transparent surfaces.

Main functions:

- Scratch tests.

- Indentation tests (creep-coverage of contact).

- Fatigue tests in scratch.

Main characteristics:

- Imaging system for in-situ vision of contact and for footprint coverage follow-up.

- Thermic chamber (Tests temperatures between 5°C and 60°C and controlled humidity).

- Displacement speed in scratch: 1µm/s 10mm/s.

- Normal load from 0.05 to 25N.

- Indentor (spherical, conical, pyramidal, …) of curvature radius comprised between 10µm and 25mm

Complementary equipment:

- Rotating module for high speed tests (6m/s) ;

- Interferometric microscope for surfaces observation.

4. JKR Dynamique

Instrument allowing the investigation of contact (adhesion, surface energy) bewteen a soft and a rigid matter or between two soft matters.

Main characteristics:

- Temperature control (betweenn -40°C and 110°C) and of humidity.

- Normal load comprised between 0.05N and 10N.

- Frequency from 0.02Hz to 20Hz.

- In-situ vision of the contact.

Volumetric properties characterizations

1. X-Ray tomograph

Observation and analysis of micro structure of samples.

Main characteristics:

- Resolution between 0.4µm and 100µm.

- 2 sources:

- 50 - 150kV

- 40 - 160kV

- 2 imagers:

- Flat panel

- CCD

Complementary equipment:

- Compression/traction module with temperature control.

- Indentation module.

- Humidity control cell

2. Instrumented traction device

Traction, compression, shearing, flexion and DMA tests.

Main characteristics:

- Applicable force until 10 kN.

- Thermal chamber (temperature from -80°C to 200°C).

Complementary equipment:

- Imagery system allowing image correlation.

3. Dynamic traction appartus (INSTRON ElectroPlus E3000)

Traction, compression and DMA tests.

Main characteristics:

- Force sensors of 10N, 100N and 1kN.

- Thermal chamber (temperature from -80°C to 200°C)

Complementary equipment:

- Extensometer video

4. DMA Mettler Toledo

Complex elasticity module depending on the temperature and the traction, compression, shearing and flexion frequency.

Main characteristics:

- Solicitation frequency comprised between 0.001 and 100Hz

- Applicable force from 0.01mN to 10N

- Maximal displacement of the traverse of 1 mm.

- Thermal chamber (temperature between -170°C and 160°C)

- Hygrometric chamber (rH% between 0 and 80% for a temperature range between 5 to 80°C)